Worth Higgins & Associates is the largest sheet-fed commercial printer in Virginia. That’s a fact. And we believe that fact is a reflection of our high standards. We obsess over details that make the difference between being simply the largest company in our category and being both the largest and the best. Are we there yet? Our customers are the judge of that. But as they vote by bringing us such a high volume of business, we’re inclined to believe that quality has something to do with our size.

Worth Higgins & Associates is the largest sheet-fed commercial printer in Virginia. That’s a fact. And we believe that fact is a reflection of our high standards. We obsess over details that make the difference between being simply the largest company in our category and being both the largest and the best. Are we there yet? Our customers are the judge of that. But as they vote by bringing us such a high volume of business, we’re inclined to believe that quality has something to do with our size.

Worth Higgins & Associates has achieved the level of G7 Process Control Master Qualification by demonstrating a thorough knowledge and skill of the fundamental best practices of process control in graphic communications production environment.

DIE CUTTING

Die Cutting

Die cutting adds shape and dimension to a printed product. Our large-format, high-speed die-cutting press works like a cookie cutter to create engaging, intriguing results that need not be at all “cookie cutter” in the imaginative potential they offer.Press Specs and Sheet Info

Our high-speed die-cutting press uses a 28” x 40” sheet and is powerful enough to make deep impressions with an accuracy level that produces the finest detail. A library of dies is available to help inspire inspire our customers’ designs and reduce costs.

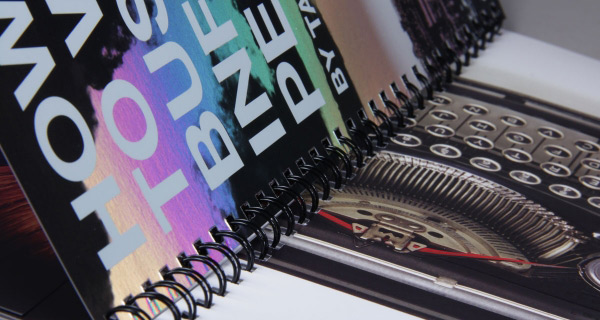

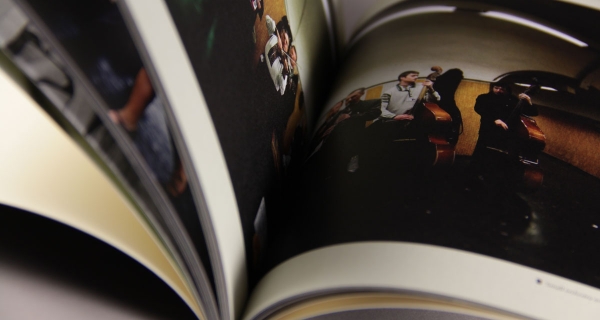

FINISHING & BINDING

Finishing & Binding

Much of the printing we do becomes simple books and brochures. But our finishing capabilities are comprehensive. They include conventional binding (folding, saddle stitching, die cutting, scoring and perforating), foil stamping and embossing, automated pocket folder conversion, collating and re-moistenable gluing, perfect binding, Wire-O binding and film laminating. We outsource less than 1% of the finishing our customers request.Finishing Types

- Saddle-stitching

- Wire-O binding

- Perfect binding

- Glue binding

- Spiral binding

- Automated pocket folder conversion (including box pocket)

- Re-moistenable gluing

- Pattern gluing

Resources

Foldfactory.com is a valuable resource for custom folding templates, die lines, folding ideas and inspirational videos. http://www.foldfactory.com/index.php

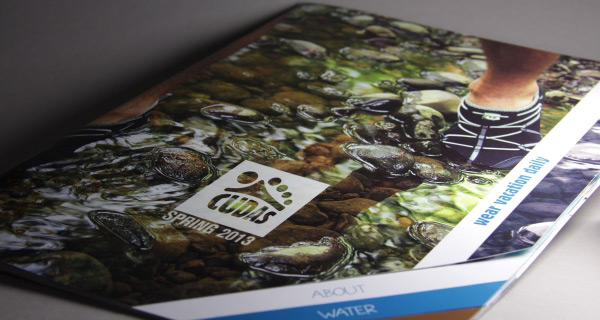

UV PRINTING

UV Printing

UV coating and UV inks are another way Worth Higgins & Associates gives customers the ability to transform a standard printed piece into something truly distinctive and even artistic. UV effects are not limited to paper substrates. Plastics, synthetics, foil, static-cling materials, Tyvec® and Teslin® are among the many possibilities for creating UV magic.

Because they are cured under ultraviolet lamps. UV inks dry instantly and stay on the surface of the printed sheet rather than being absorbed. They can be dry trapped inline on a single pass. UV inks make colors appear richer and more intense, especially on uncoated sheets. A range of coating options from flood and spot to gloss, dull, textured or reticulating can be used to create special effects and supersaturated images. Flood dull UV varnish makes a printed piece especially resistant to fingerprints.

PRE-PRESS & PROOFING

Prepress & Proofing

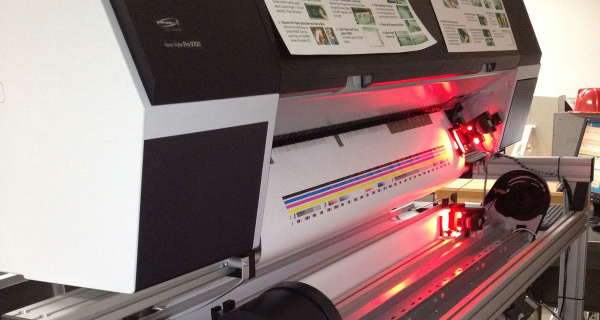

There is no better proof of our commitment to quality than our prepress and proofing processes. Our state-of-the-art CIP3 system electronically integrates prepress and pressroom equipment to automatically communicate job specifications from department to department. In addition to saving time, the system greatly reduces the possibility of error.Speed & Acuracy

Digital workflow in our prepress department – including direct-to-plate technology and fully automated plate making – increases the accuracy of contract color proofs and trapping and image assembly. It also increases the speed with which we are able to process customer files.Proofing Options

Worth Higgins & Associates offers a hierarchy of proofing options that allow customers flexibility in how they review and revise a job in progress. Those options include remote soft proofing, low-resolution HP proofs and high-resolution Epson proofs. Our goal throughout the prepress and proofing processes is to assure that there are no differences between what a customer wants to achieve and what we deliver.

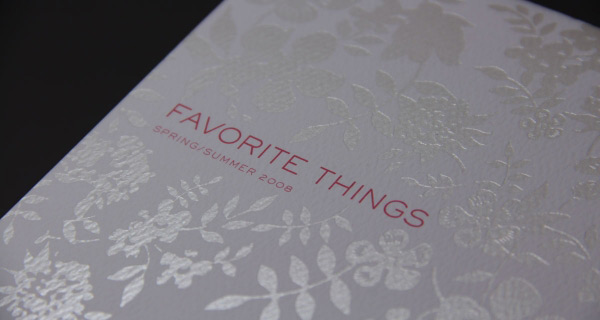

EMBOSSING

Embossing

Whether it’s blind, registered, rounded or sculpted, embossing from Worth Higgins & Associates takes a printed piece to a whole new level. Add texture and dimension and elevate your image all at the same time for a 3-D effect.

FOIL STAMPING

Foil Stamping

Foil stamping can embellish an image with striking effect. It’s a part of our business that is more craft than technology. Whether the choice is metallic, pigment, pearl or dusted foil, the results are sure to shine.

PRESS ROOM

Press Room

The pressroom at Worth Higgins & Associates is where the latest printing technologies and the experience and standards of our company converge. Nearly a dozen certified Master Pressmen are in charge of processes that produce press sheets that customers typically approve on the first or second pull. Our on-site ink technician mixes ink, makes drawdowns, manages ink inventory and provides technical assistance.Quality & Innovation

Our pressroom also employs a number of supplemental technologies that enhance product quality, increase the speed of the process and help reduced costs. Spectrodensitometers read ink densities across the approved press sheet, locking in that data profile so color remains consistent throughout the press run. Every press is color calibrated to match Epson color proofs. Aqueous coating units on three presses create a variety of surface finishes and enable us to deliver printed sheets dry enough for immediate handling so that the finished product can be completed more quickly. Small-format thermography is also available.Press Specs

- Komori 640LS 6-color with aqueous coating

- Komori 640GL with UV inks and coating and aqueous coating

- Komori Lithrone 628 6-color with aqueous coating

- Komori Spica 29P 4-color perfecting press

- Two Hamada 665CD 2-color presses

- Magnum MX6 ink mixers – one for conventional inks, the other for UV inks